![]() The Emplex MPS6300 & MPS6700 Validatable Series Band Sealers boast a wide range of standard features and capabilities. These continuous feed, variable speed machines include: one pair of air pressurized, digitally controlled heaters bars; one pair of air flow, air pressurized cooling bars; with the new PLC control system with touch screen HMI interface for programming and monitoring your sealer performance and a safety interlock switch which turns the machine off when the control panel is opened. There is also an internal switch which turns off the front heater bars, improving the sealing of Tyvek pouches. Calibration can be done at the Emplex factory or by your own testing facilities. all seal are created using economical etched Teflon bands which maintain high seal quality and produce consistently strong, clean seals on all heat sealable bags.

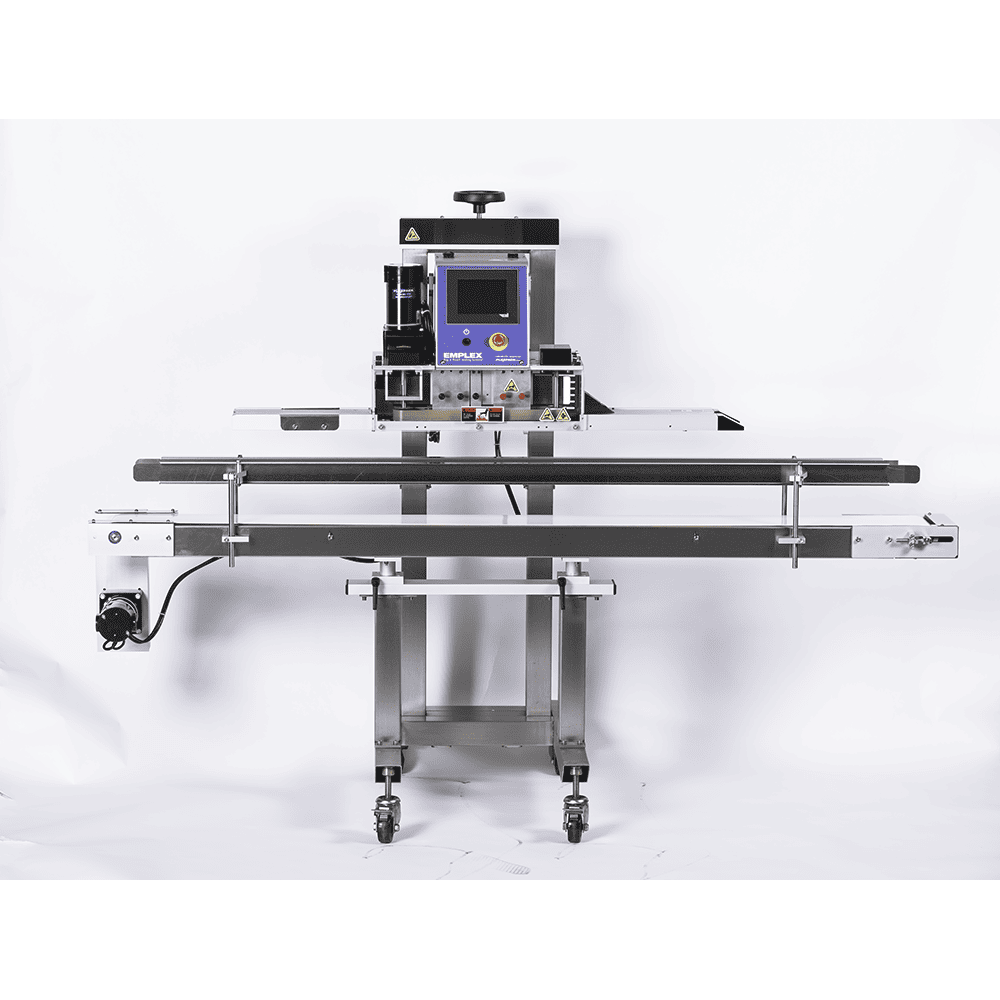

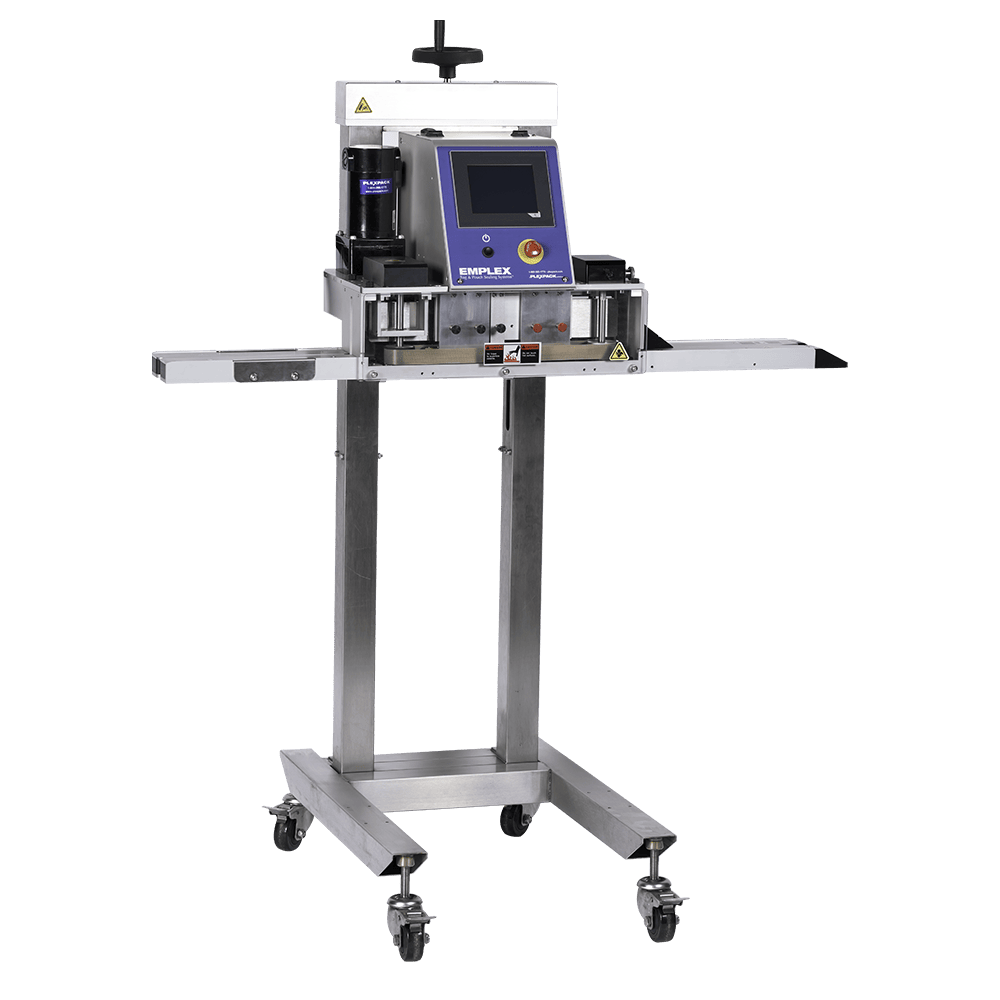

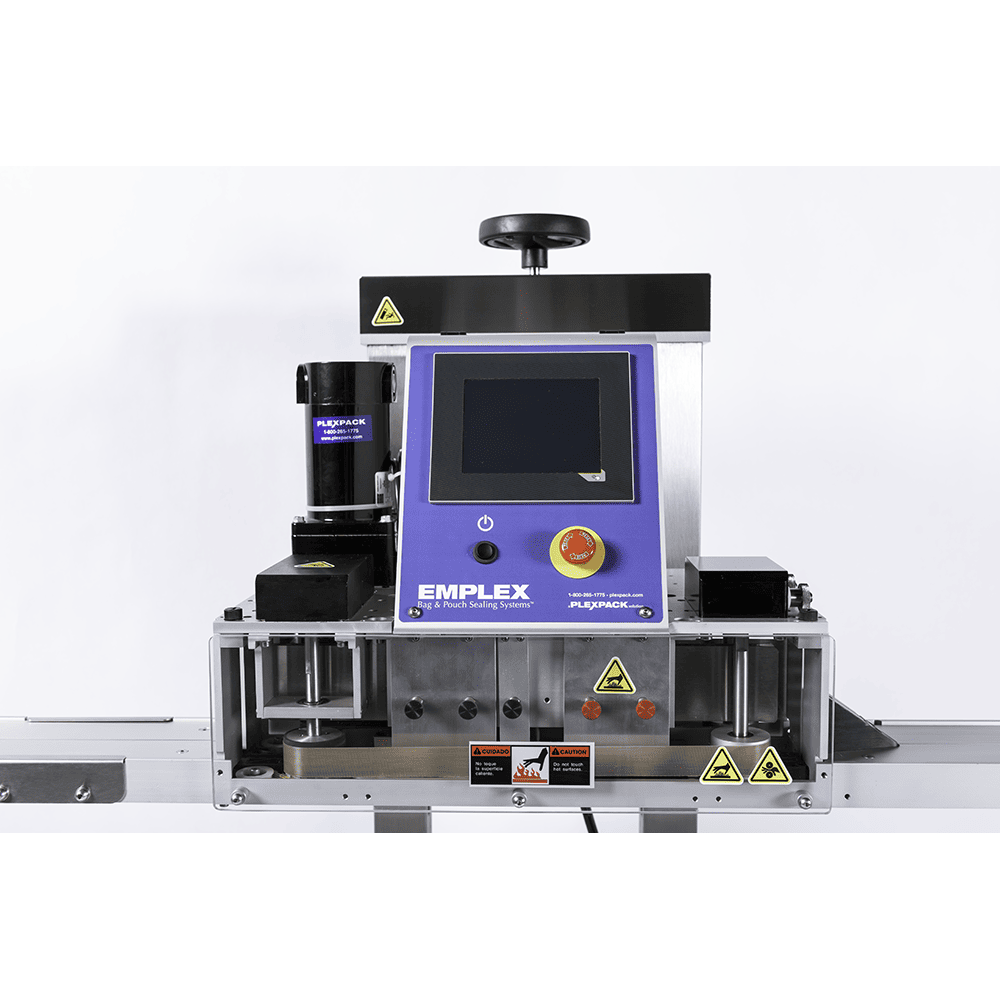

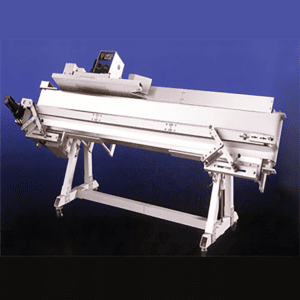

The Emplex MPS6300 & MPS6700 Validatable Series Band Sealers boast a wide range of standard features and capabilities. These continuous feed, variable speed machines include: one pair of air pressurized, digitally controlled heaters bars; one pair of air flow, air pressurized cooling bars; with the new PLC control system with touch screen HMI interface for programming and monitoring your sealer performance and a safety interlock switch which turns the machine off when the control panel is opened. There is also an internal switch which turns off the front heater bars, improving the sealing of Tyvek pouches. Calibration can be done at the Emplex factory or by your own testing facilities. all seal are created using economical etched Teflon bands which maintain high seal quality and produce consistently strong, clean seals on all heat sealable bags.

Sealers ship in 6-8 Weeks, FOB: Toronto, Canada. Must ship LTL.

Download Emplex-MPS6300-6700-Brochure

FILL IN AND SUBMIT THE FORM BELOW FOR A FREE EVALUATION AND QUOTATION INCLUDING FREIGHT.

Inquiry form

RFQ

Validation Control – The MPS Validatable Series Band Sealers has a control system that runs the sealer with a PLC and includes 2 or 3 closed loop temperature controls, 1 closed loop speed control, 1 closed loop air pressure control. The program menu can hold up to 9 recipes for easy changeover to different bags. The alarm menu ensures that bags are sealed only within programmed parameters, when the machine will stay in reverse so that no bag can be loaded while the sealer is out of tolerance.

Add-On Versatility –A number of add-on options modify and enhance the sealing functionality of this series. These options include: trimmers, printers, embossers, conveyors, perforation units and more. This add-on principle means you can add-on any of these options at any time to the sealing unit, even after the purchase. Most take just a few bolts to add-on.

Strong Support Capability – Emplex’s exclusive infeed system is capable of supporting significant bag weights without the use of a conveyor. Typically, the MPS6300 can support a 10” wide bag containing 2 pounds of product. More weight can be supported with wider bags, and less weight is supported as the bag narrows. For more weight or added versatility use the Conveyorized MPS6700 Series of Validatable Band Sealers.

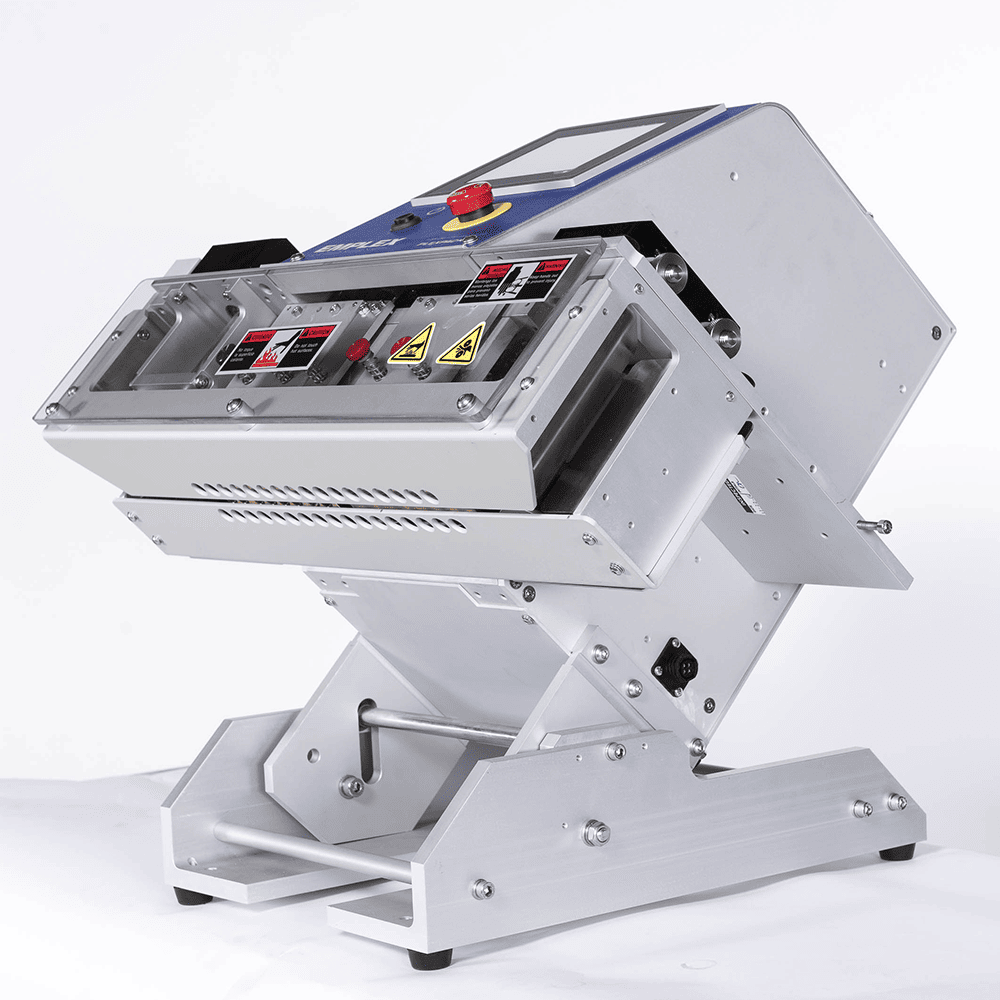

Fast Routine Maintenance – When sealing bands need to be replaced, Emplex’s unique design offers quick and easy change-over. No tools are required and it takes about a minute to change. Easy access to the sealer’s internal components and simple construction keep routine maintenance to a minimum.

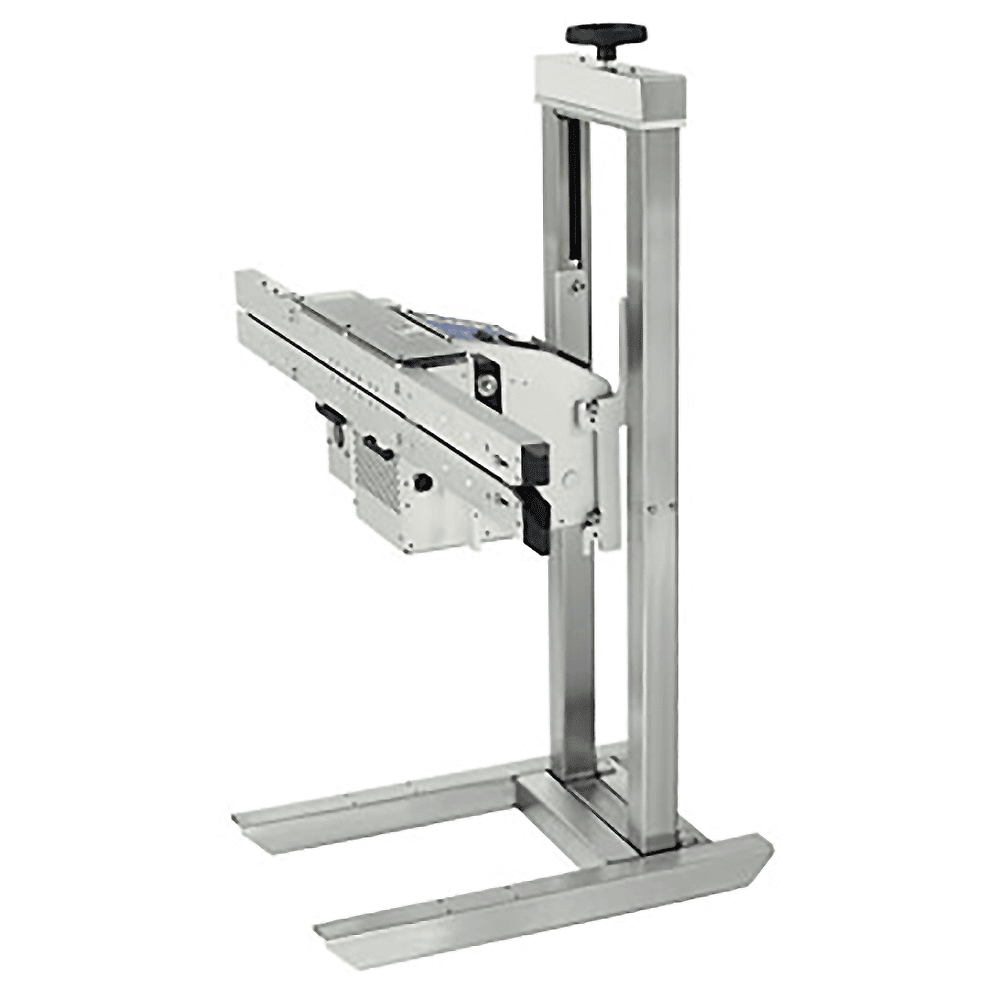

Unique Stand Design – The newly designed stainless steel stand is as functional as it is durable. The stand is height adjustable by crank wheel. For people who want to run the machine horizontally (30-36″ off the ground), different brackets are used. If you want to run the machine both vertically and horizontally, a second set of optional mounting brackets is all that is needed instead of a whole new frame. Casters now included at no extra charge.

New Update Design – the next generation of MPS6000 series band sealers is now available. Here is a summary of the key upgrades:

- Switched from Imperial to Metric tooling & measurement

- Stainless Steel Crank Adjustable Stand

- Improved Cooling Fan for Cooling Section

- Improved Pressure Roller Design

- See-Through Cover on Seal Section

- Removable Seal Section

- PLC Control System

- Cool Down operation standard

- True Interlock Switch on control box

- Improved Solid State Relay

- Optional heater fail alarm

Compact and portable, the MPS6340 is the table-top version of the MPS6300. Ideal for lightweight sealing applications (up to 8 0z.). The newly re-designed MPS 6340 stand allows the sealing head to run at 0º, 45º or 90º for optimum efficiency.

The MPS6300/6700 Band Sealers can be equipped with the ER60 emboss coder. The ER60 holds up to 8 characters of standard type and 13 characters of slim type, and is available in single line or double line versions.

The MPS6300/6700 Band Sealers can be equipped with the front-end bag top trimmer and vacuum trim removal combo. The blade is height adjustable for accurate trim positioning. The trimmer unit is easily and quickly removed for servicing or non-trimmed sealing.

|

||||||||||||||||||||||||||||

|

Emplex MPS6300 & MPS6700 Validatable Band Sealers

|

||||||

| Part Number | Description | |||||

| MPS6300 | Validatable Band Sealer with Adjustable Height Stand | |||||

| MPS6340 | Validatable Table-Top Band Sealer | |||||

| MPS6700 | Conveyorized Validatable Band Sealer with 6″ x 6′ Conveyor | |||||

|

OPTIONAL ACCESSORIES

|

||||||

| 4QA420M-1 | Emplex Inline Bag Trimmer | |||||

| 1QA967-A | Inline Exit Trimmer | |||||

| K008020 | Elfin 1S Rail Mounted Inkjet Printer | |||||

| 1QA912-A | Inline ER60 Emboss Coder | |||||

| TypeSet1-E | Type Set Kit for ER60 Emboss Coder (35 pieces) | |||||

| 4QA083M-A | Infeed Product Shelf for Emplex Basic Band Sealer | |||||

|

FOB: Toronto, Canada. Must ship LTL.

|

||||||

Related products

-

Food Sealers

PlexPack VacPack Vacuum Sealer

-

Band Sealers

Emplex ACS Bag Sealing System

-

Conveyorized

Pacemaker Incline Conveyor