Easy Infeed with the Emplex MPS7200 V-Mouth Band Sealers

Easy Infeed with the Emplex MPS7200 V-Mouth Band Sealers

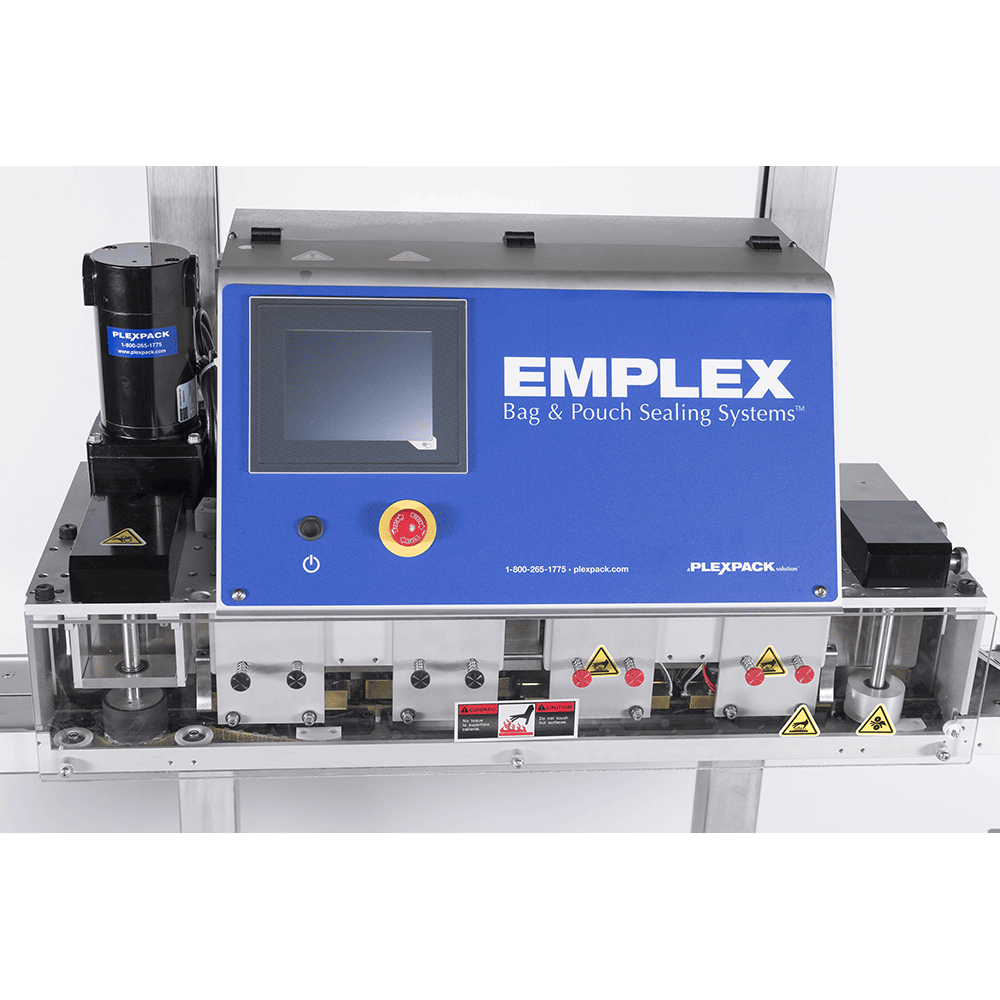

Engineered for demanding environments, the Emplex MPS7200 series of bag sealers tackle heavy-duty, high-speed production requirements with ease. The V-Mouth infeed allows for ease of loading the bag either by hand or on a conveyor. Like all MPS7000 Series the MPS7200 is built standard with 10” of heating and 10” of cooling (double the capacity of the MPS6000 series), each 5” heating section is controlled by the new PLC control system with touch screen HMI interface for programming and monitoring your sealer performance. Variable speeds can be reached in excess of 750” per minute.

Sealers ship in 6-8 Weeks, FOB: Toronto, Canada. Must ship LTL.

Download Emplex-MPS7100-7500-Brochure

Need a semi-automatic sealing system? Look at the Emplex ACS Bag Sealing System

For Replacement parts go to Emplex MPS Series Parts

FILL IN AND SUBMIT THE FORM BELOW FOR A FREE EVALUATION AND QUOTATION INCLUDING FREIGHT.

Inquiry form

RFQ

Emplex MPS7200 V-Mouth Band Sealers

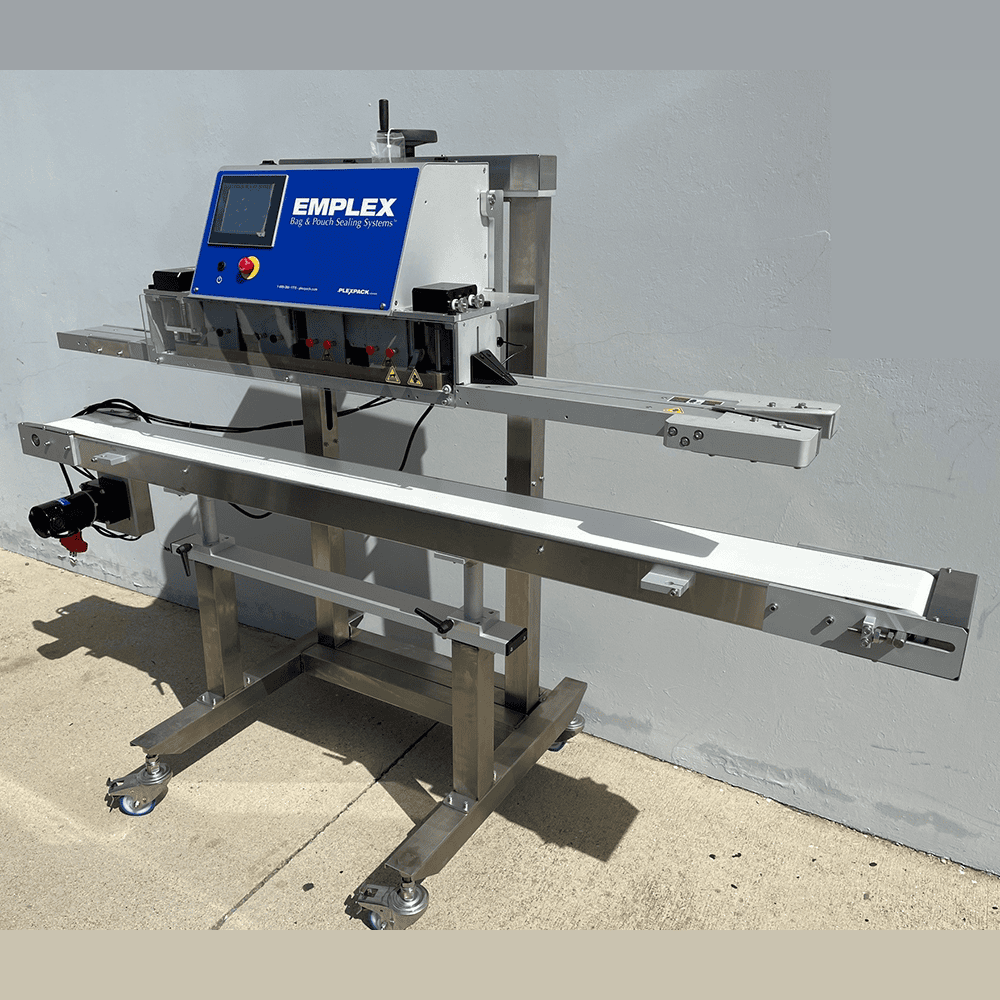

The Emplex MPS7200 shown with extended infeed conveyor.

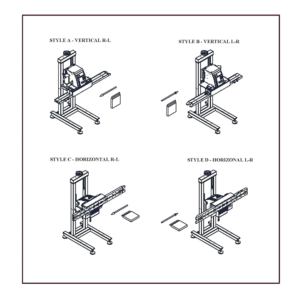

The Emplex MPS7200 V-Mouth band sealer is a versatile, high-performance sealing machine designed for industrial and commercial packaging applications. Its unique V-mouth infeed system provides smooth and consistent handling of pouches, especially for hard-to-hold bags or materials. This design enhances the efficiency and accuracy of the sealing process, making it ideal for packaging bulk products, powders, or items that require special handling.

The MPS7200 series utilizes variable pressure sealing bars for the sealing process which accommodate for variations in bag thickness or composition, ensuring hermetic seals every time. All seals are created using economical etched Teflon bands. The infeed system is capable of supporting significant bag weights without the use of a conveyor. Typically, the MPS7200 can support a 10” wide bag containing 2 pounds of product.

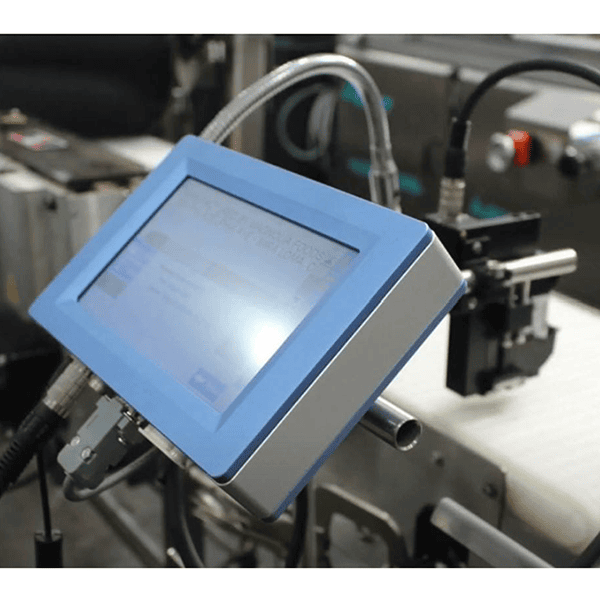

Equipped with PLC controls: The MPS7200 bag sealer offers easy operation, letting users adjust settings and monitor performance through an intuitive interface. This ensures that the sealing process can be fine-tuned for different bag types and materials, enhancing its adaptability across various packaging needs.

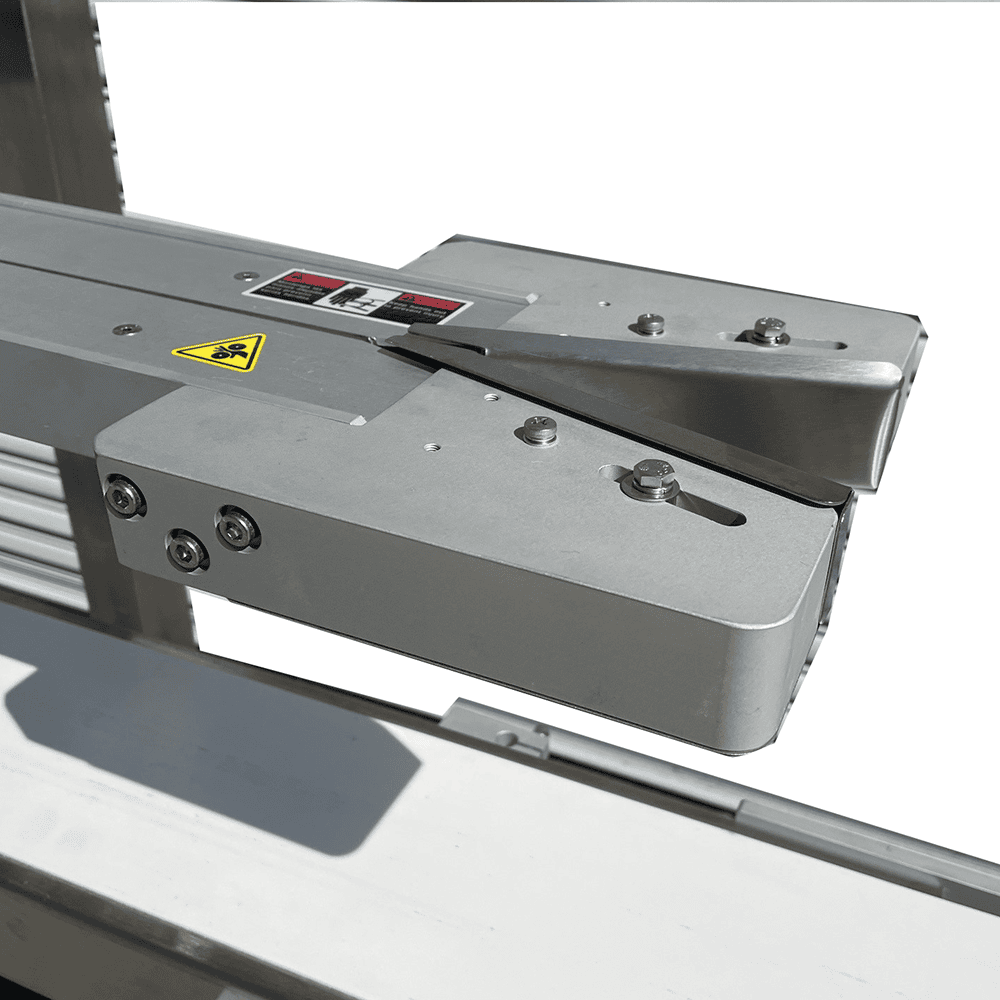

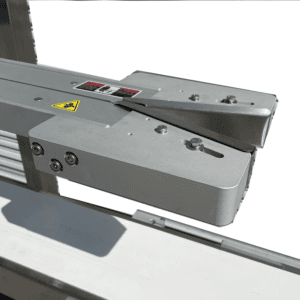

V-Mouth Infeed: The MPS7200 sealer head is designed so certain bags (stiff bags or bags that lay flat) can automatically be fed into the sealer head without an operator feeding it in.

Conveyorized Units: For bags that require more support, the MPS7200 can come with an inline conveyor. The standard conveyor size is 6” wide x 6’ long, with a fully family of conveyor options and sizes available to meet your needs. All conveyors are stainless steel, food-grade belt conveyors, complete with adjustable guide rails and are easy to manually raise and lower.

Add-On Versatility: A number of add-on options modify and enhance the sealing functionality of this sealing machine. These options include: trimmers, printers, embossers, conveyors, perforation units and more. This add-on principle means you can add-on any of these options at any time to the sealing unit, even after the purchase. Most take just a few bolts to add-on.

Fast Routine Maintenance: When sealing bands need to be replaced, Emplex’s unique design offers quick and easy change-over. No tools are required and it takes about a minute to change. Easy access to the heat sealer’s internal components and simple construction keep routine maintenance to a minimum.

The MPS7200 Band Sealer can be equipped with the Inline Elfin Thermal Inkjet Printer. The Elfin Printer has a 5″ LCD Touch Screen Display with up to 600dpi high resolution printing directly onto the bag using special ink.

The MPS7200 Band Sealers can be equipped with the ER60 emboss coder. The ER60 holds up to 8 characters of standard type and 13 characters of slim type, and is available in single line or double line versions.

The MPS7200 Band Sealers can be equipped with the front-end bag top trimmer and vacuum trim removal combo. The blade is height adjustable for accurate trim positioning. The trimmer unit is easily and quickly removed for servicing or non-trimmed sealing.

|

|||||||||||||||||||||||

|

Emplex MPS7200 Heavy-Duty Band Sealers with V-Mouth Infeed

|

||||||

| Part Number | Description | |||||

| MPS7200 | Dual-Heat Band Sealer with Adjustable Height Stand and V-Mouth Infeed | |||||

|

OPTIONAL ACCESSORIES

|

||||||

| C2-6-6 | Emplex Inline 6″ x 6′ Belt Conveyor | |||||

| CBA-12-7 | Emplex Inline 12″ x 7′ Roller Belt Conveyor | |||||

| CBA-12-10 | Emplex Inline 12″ x 10′ Roller Belt Conveyor | |||||

| 4QA420M-1 | Emplex Inline Front End Bag Trimmer | |||||

| 1QA967-A | Inline Exit Trimmer | |||||

| K008020 | Elfin 1S Rail Mounted Inkjet Printer | |||||

| 1QA912-A | Inline ER60 Emboss Coder | |||||

| TypeSet1-E | Type Set Kit for ER60 Emboss Coder (35 pieces) | |||||

| 4QA083M-A | Infeed Product Shelf for Emplex Basic Band Sealer | |||||

|

FOB: Toronto, Canada. Must ship LTL.

|

||||||

Find more information on the Plexpack Website

Related products

-

Conveyorized

Pacemaker Incline Conveyor

-

Impulse Sealers

PlexPack VacPack Medical Vacuum Sealer