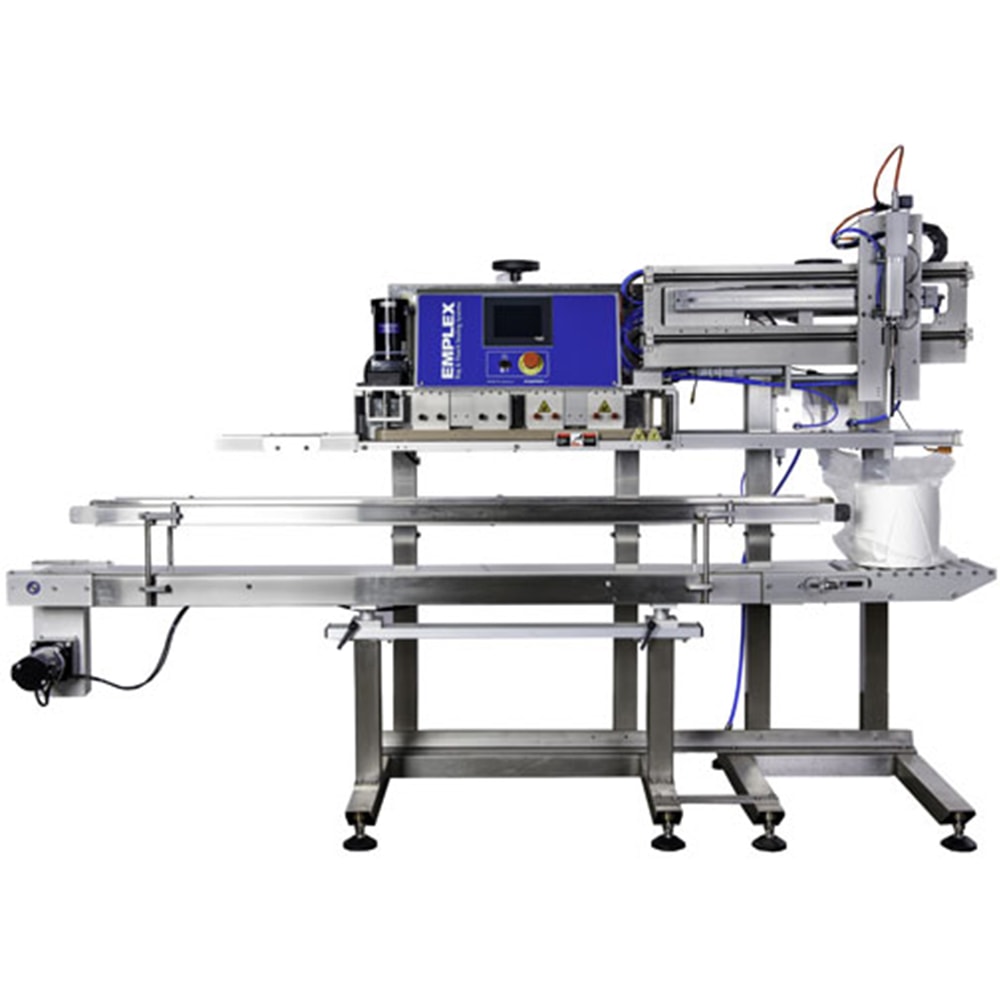

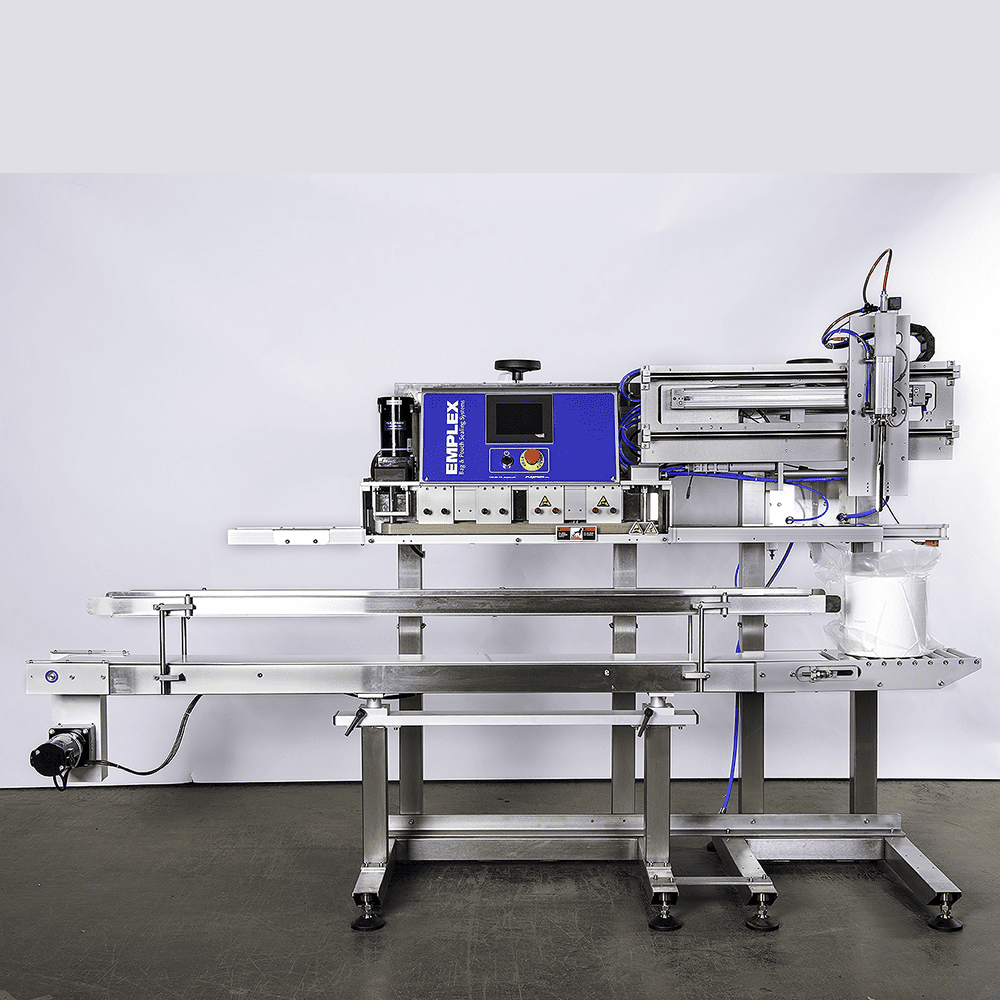

The Emplex MPS7103S & 7503S Band Sealers

The Emplex MPS7103S & 7503S Band Sealers

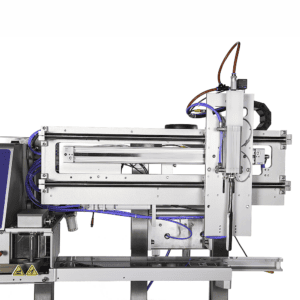

are new high speed, continuous sealing machines equipped with a vacuum and nitrogen gas flush system with conveyor (MPS7503S) or no conveyor (MPS7103S.

Download Emplex-VGF-Series-Brochure

Don’t need the speed of a band sealer? Try the VacPack VS1 Table Top Vacuum Sealer

Do you need a high speed band sealer, but not the vacuum/gas system? Try the Emplex MPS7100 & MPS7500 Band Sealers

Sealers ship in 6-8 Weeks, FOB: Toronto, Canada. Must ship LTL.

FILL IN AND SUBMIT THE FORM BELOW FOR A FREE EVALUATION AND QUOTATION.

Inquiry form

RFQ

The Emplex MPS7103S – seen here sealing snack pouches – is an ideal solution

for operations that require modified atmosphere packages with high throughput and efficiency.

The Emplex MPS7103S & MPS7503S sealing machines create high quality moisture proof, oxygen free packages. It is ideal for customers that require higher capacity output than our VacPack impulse vacuum sealers.

Typically, customers requiring more than 5 bags a minute find a greater return on investment by choosing a continuous band vacuum sealer. Satisfied customers include producers of coffee, snacks, pre-baked goods, electronics, medical products, meat, produce and fresh & dried foods.

The MPS7503S bag sealer includes a synchronized conveyor for a more automated system. The conveyor ensures easy, consistent handling and product orientation as bags enter and exit the heat sealer. The MPS7503S provides high quality, hermetic seals on all moisture-barrier bag materials and is capable of sealing bags up to 12 mil in thickness or 6 mil maximum when gusseted at required production speeds.

The vacuum and/or nitrogen gas flush system on the heat sealer removes oxygen resulting in longer shelf life, product integrity, and protection against discoloration. For snack products, a gas flush only system can create a cushion-like buffer against damage.

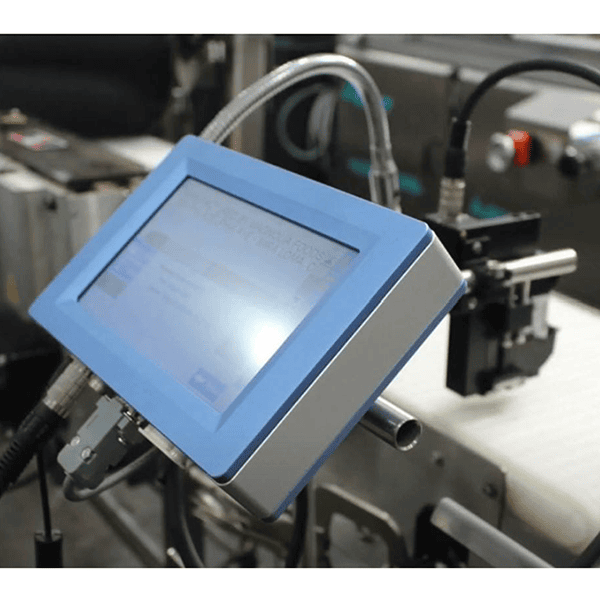

All of the Emplex MPS7000 Series bag sealers are equipped with the new PLC control system and touch screen operator interface. They can also be equipped with an IP-66 washdown electrics, bag top trimmer, emboss coder, dry ink printer, or ink jet printer. Designed for 24/7 operation, these sealers are suitable for all production environments.

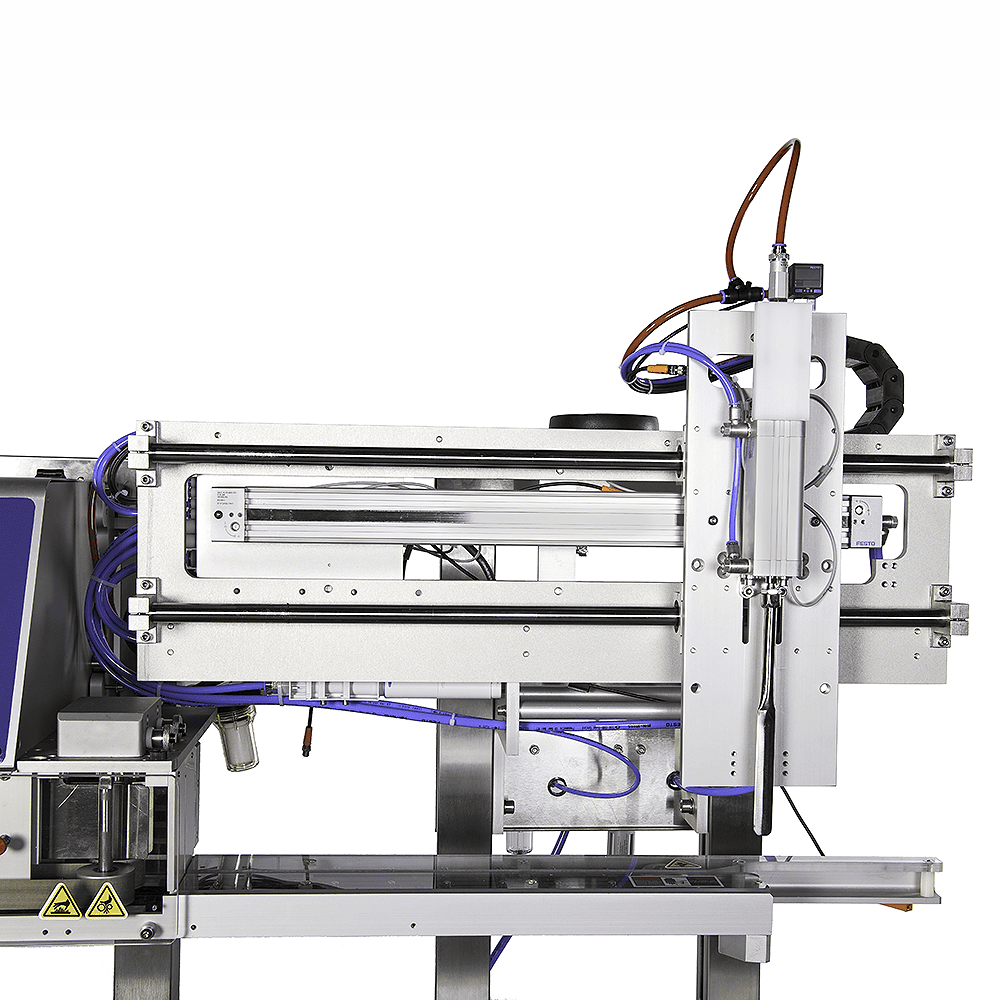

The MPS7103S & MPS7503S Band Sealers can be equipped with the Inline Elfin Thermal Inkjet Printer. The Elfin Printer has a 5″ LCD Touch Screen Display with up to 600dpi high resolution printing directly onto the bag using special ink.

The MPS7103S & MPS7503S Band Sealers can be equipped with the front-end bag top trimmer and vacuum trim removal combo. The blade is height adjustable for accurate trim positioning. The trimmer unit is easily and quickly removed for servicing or non-trimmed sealing.

You can find more information about these sealing machines on the Plexpack website

Related products

-

Food Sealers

PlexPack VS1 Vacuum Sealer

-

Band Sealers

Emplex MPS6500 Band Sealers with Conveyor