Heat Sealer Medical Validation

Medical Packaging: Packaging plays an important role in assuring the sterility of medical devices and instruments from manufacture to point of use. Applying effective heat seals to the bag or pouch of terminally sterilized medical devices is arguably the most critical step to ensure the sterility of a product when it comes into contact with a patient. No matter how good the sterilization and disinfection process is, if the packaging and seal closures of a medical pouch are compromised, there is significant risk of product contamination during shipping and storage that could pose serious danger to the patient.

Time, Temperature and Pressure Control

Regulations: The regulatory standard for validation of the heat sealing process for medical applications is ISO 11607-2:2006. It specifies the validation requirements for the forming, sealing, and assembly process for the packaging of terminally sterilized medical devices. The objective of seal process validation is to document the sequence of events in which the process is established to produce effective seals that maintain sterility to the point of use and do so in a repeatable, reliable way. ISO 11607 characterizes heat sealing as achievable with a bar sealer (constant heat), impulse sealer, or a continuous feed sealer (rotary band sealer) and defines the critical parameters to create a proper seal as temperature, pressure, and heat and dwell time. These critical process parameters should be controlled, monitored, and documented. In the event that the critical process parameters are outside of predetermined tolerances, alarms, warning systems and/or machine stops are initiated. Additionally, the critical process instruments and sensors must be calibrated.

Temperature: A digital temperature controller or PLC monitors and controls the temperature of the sealing bars or sealing wire element based on feedback from the temperature sensor. For an additional level of security, temperature verification ports that are accessed externally can allow an operator to connect a calibrated temperature sensor and verify temperature accuracy against the sealer’s temperature controller.

Pressure: Readings on the seal jaws or heating/cooling bars are more accurate if pressure is delivered through pneumatic air solenoids which can be calibrated and digitally controlled to provide consistent sealing pressure. This is in contrast to spring-based pressure which is difficult to measure accurately and not calibrated externally.

Time: In bar sealers and impulse sealers the seal time, dwell time and jaw closure time are measured and controlled by the digital temperature controller or PLC. In continuous feed (rotary band) sealers seal time and dwell time are determined by band speed which is controlled by a digital speed control or PLC.

Certification & Monitoring: All instrumentation, sensors, displays, and controllers are certified as calibrated and written calibration procedures are developed. Merely setting critical sealing parameters is not sufficient and all monitoring functions should show actual conditions.

Our Solutions:

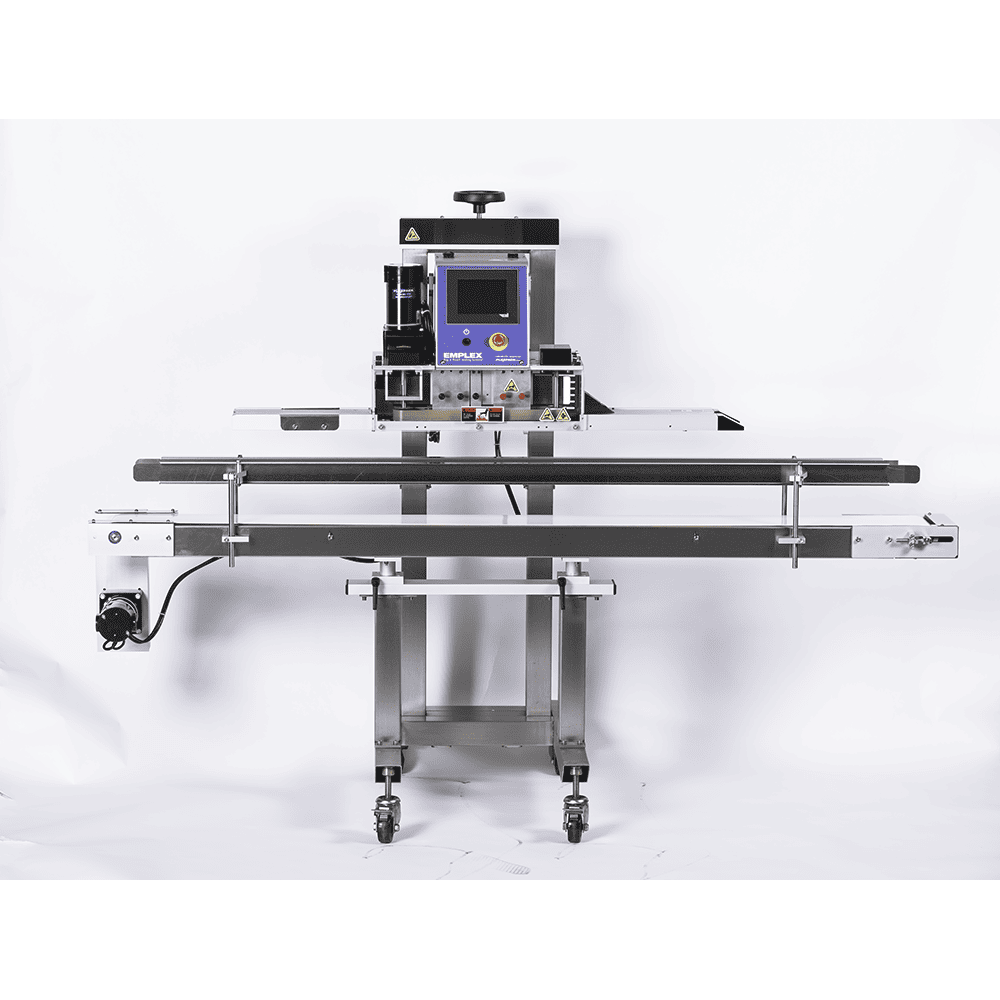

Emplex Validatable Band Sealers – have a control system that runs the sealer with a PLC and includes 2 or 3 closed loop temperature controls, 1 closed loop speed control, 1 closed loop air pressure control.

Plexpack VacPack Medical Impulse Sealers and Vacuum Sealers – continuously control and verify temperature, speed, pressure during production with PLC control system.

Related products

-

Impulse Sealers

PlexPack VacPack Medical Vacuum Sealer

-

Band Sealers

Emplex MPS6300 & MPS6700 Validatable Band Sealers