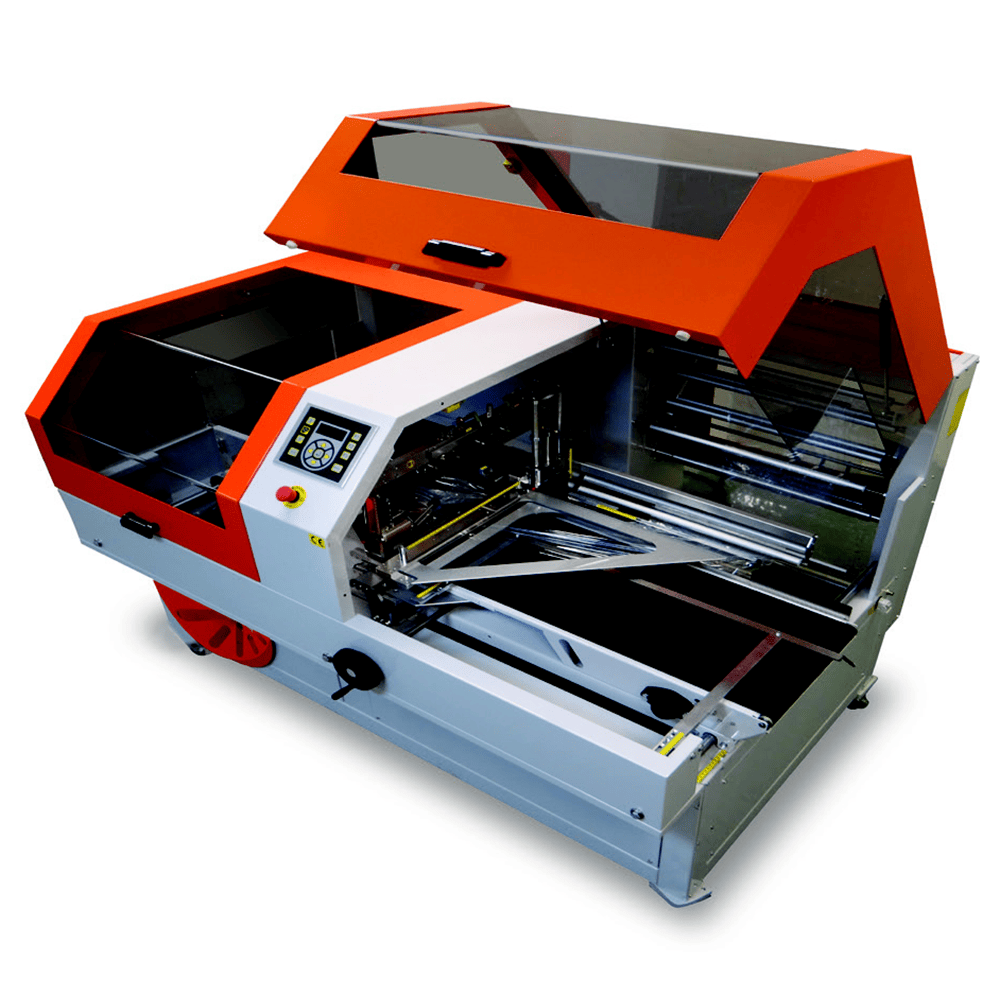

The Clamco 6800CS is an economical intermittent motion, automatic side seal shrink wrapper. Compared to traditional automatic L-bar sealers, the 6800CS side sealer offers a unique advantage: it is capable of packaging products of virtually any length and at a high rate of speed. Using standard polyolefin or polyethylene center-folded shrink film, the versatile 6800CS side sealer wraps up to 4200 packs per hour.

Clamco-6800CS-Side-Sealer-Brochure

FILL IN THE FORM BELOW AND SUBMIT FOR A FREE CONSULTATION & QUOTE

Inquiry form

RFQ

Excellent for a wide variety of package sizes, the 6800CS will accommodate parcels measuring 15.75” wide by 7.85” high, by almost any length – down to a package the size of a small book. The side sealer features an adjustable film inverting head, low, easy-to-reach film cradle, and accessible film adjustment controls that enable the operator to setup and begin production quickly and easily.

The intuitive, easy-to-navigate user interface may be learned quickly for operators of average skill level. The digital display indicates key packing statistics, including: production rate, packaging efficiency, 20 program memory and more. Twin doors provide easy access to all functional areas.

User benefits

• Temperature controlled system provides repeatable, strong seals

• Power take-away and tunnel conveyors share a common height adjustment to provide for smooth product transfer

• Heavy-duty design for 24×7 productivity, with minimal maintenance

• Scrap collection area for reduced cleanup time clean-up time

• Live/dead roller system allows the use of a wide variety of films

• Dwell control provides additional flexibility

• Powerful magnetic hold down for consistent trim seal pressure

Set-up benefits

• Automatic seal centering on both the side seal and the cross seal, for a cleaner, more attractive package

• Automatic product length detection allows individual or multiple products to be wrapped

• Quick changeover and 20-program memory enables machine set-up in fewer than five minutes

• Low film cradle with inverted head for easy film loading

Operating benefits

• Seals packages of virtually any length – quickly and efficiently

• Integrates easily with shrink tunnel

• Use with a wide variety of films

• Twin door access to key functional areas

• PTFE-coated side seal blade works with standard shrinkfilms (up to 120 gauge polyolefin)

• Trim take-up spool keeps work area clean

• On-board troubleshooting menu

Safety benefits

• Fully enclosed mechanical areas ensure operator safety

• Smooth and quiet operation reduces noise

• Compliance with CE regulations ensures improved safety

• Easy-to-reach emergency shut-off

Options and Accessories

• Polyethylene cross seal bar for 0.6–3.0 mil. polyethylene film

• Stainless steel frame for applications in the food industry

• Print registration for pre-printed film

• Safety photocell prevents cross seal bar from contacting product

SPECIFICATIONS

- Conveyor Speed: 25–95 ft/min

- Production capacity: up to 70 cycles per minute

- Cross seal bar width: 9.75”

- Maximum product width:15.75”

- Maximum product height: 7.85”

- Maximum product length: unlimited

- Maximum film width: 23.5”

- Maximum film roll diameter:13.75”

- Electrical requirements: 220 Volt, 7 Amps, 3 Phase

- Air requirement: 90 psi

- Shipping weight: 1,800 lbs

- Machine size (w x d x h): 86” x 61” x 61”

Related products

-

Flow Wrapper

PAC FW-400F Flow Wrapper